Ngalaba gbọmgbọm oghere

Ụfọdụ atụmatụ gbọmgbọm na-enye nhazi pụrụ iche nke ejima ịghasa extruders. Mgbe anyị na-ejikọta gbọmgbọm ọ bụla na nhazi ihe nkedo kwesịrị ekwesị, anyị ga-eduzi ọmụmụ ihe n'ozuzu na nke miri emi nke nke ọ bụla n'ime ụdị gbọmgbọm ndị a maka otu ọrụ kpọmkwem na akụkụ ahụ nke extruder.

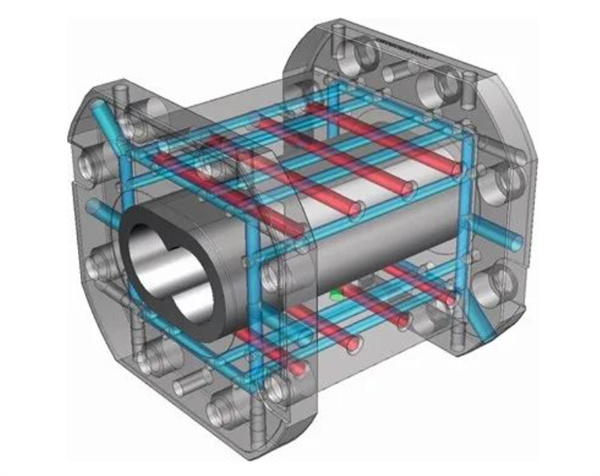

Ngalaba gbọmgbọm ọ bụla nwere ọwa nwere ụdị 8 nke skru na-esi na ya na-agafe. gbọmgbọm mepere emepe nwere ọwa mpụga iji nye ohere inye nri ma ọ bụ ịwụsa ihe na-agbanwe agbanwe. Enwere ike iji atụmatụ gbọmgbọm mepere emepe maka nri na ikpochapụ, enwere ike itinye ya ebe ọ bụla na ngwakọta gbọmgbọm dum.

Nri

N'ụzọ doro anya, a ghaghị inye ihe ahụ n'ime extruder ka ịmalite ịgwakọta. gbọmgbọm nri bụ gbọmgbọm mepere emepe emebere ka ọ nwee oghere n'elu gbọmgbọm ebe a na-esi na ya rie nri. Ọnọdụ kachasị maka drum nri bụ na ọnọdụ 1, nke bụ gbọmgbọm mbụ na ngalaba usoro. A na-atụ ihe granular na ihe ndị na-asọ asọ n'efu site na iji feeder, na-enye ha ohere ịdaba ozugbo na extruder site na mpempe akwụkwọ nri wee rute ihe nkedo.

Ntụ ntụ nwere obere njupụta na-ebutekarị ihe ịma aka ebe ikuku na-ebukarị ntụ ntụ. Ikuku ndị a na-agbapụ na-egbochi eruba ntụ ntụ, na-ebelata ikike nke ntụ ntụ na-eri nri na ọnụego achọrọ.

Otu nhọrọ maka nri ntụ ntụ bụ ịtọ barel abụọ mepere emepe na barel abụọ mbụ nke extruder. N'ebe a, a na-enye ntụ ntụ n'ime gbọmgbọm 2, na-ekwe ka ikuku ikuku na-agbanye na gbọmgbọm 1. A na-akpọ nhazi a ngwaọrụ n'azụ. Igwe ikuku n'azụ na-enye ọwa maka ikuku ga-esi na extruder pụọ na-egbochighị chute nri. Site na mwepụ nke ikuku, ntụ ntụ nwere ike inye nri nke ọma.

Ozugbo a na-enye polymer na ihe mgbakwunye n'ime extruder, a na-ebuga ihe ndị a siri ike gaa na mpaghara agbaze, ebe a na-agbaze polymer ma jikọta ya na ihe mgbakwunye. Enwere ike inye nri mgbakwunye na mpaghara mgbaze site na iji nri akụkụ.

Egwu

A pụkwara iji akụkụ tube na-emeghe maka iyuzucha; A ghaghị ịwụpụ uzuoku na-agbanwe agbanwe nke a na-emepụta n'oge usoro ngwakọta tupu polymer gafere n'ọnwụ.

Ọnọdụ kacha pụta ìhè nke ọdụ ụgbọ mmiri na-ekpo ọkụ bụ n'akụkụ njedebe nke extruder. A na-ejikọkarị ọdụ ụgbọ mmiri a na-ekpocha ọkụ na mgbapụta agụụ iji hụ na a na-ewepụ ihe niile na-agbanwe agbanwe na-ebu na polymer gbazere tupu ha esi na isi ebu. The fọdụrụ uzuoku ma ọ bụ gas na gbazee nwere ike iduga ogbenye urughuru àgwà, gụnyere ụfụfụ na mbelata mbukota njupụta, nke nwere ike imetụta nkwakọ mmetụta nke ahụ.

Akụkụ gbọmgbọm mechiri emechi

Ihe na-emekarị n'ofe akụkụ nke gbọmgbọm bụ n'ezie gbọmgbọm mechiri emechi. Akụkụ gbọmgbọm ahụ na-ekpuchi polymer gbazee kpamkpam n'akụkụ anọ nke extruder ahụ, na-enwe naanị otu oghere nwere ụdị 8 nke na-enye ohere ka etiti nke ịghasa gafere.

Ozugbo a na-enyefe polymer na ihe mgbakwunye ọ bụla n'ụzọ zuru ezu n'ime extruder, ihe ahụ ga-agafe na ngalaba nnyefe, polymer ga-agbaze, a ga-agwakọta ihe niile na-emepụta ihe na polymer. gbọmgbọm mechiri emechi na-enye njikwa okpomọkụ maka akụkụ niile nke extruder, ebe gbọmgbọm mepere emepe nwere obere ọkụ na ọwa jụrụ oyi.

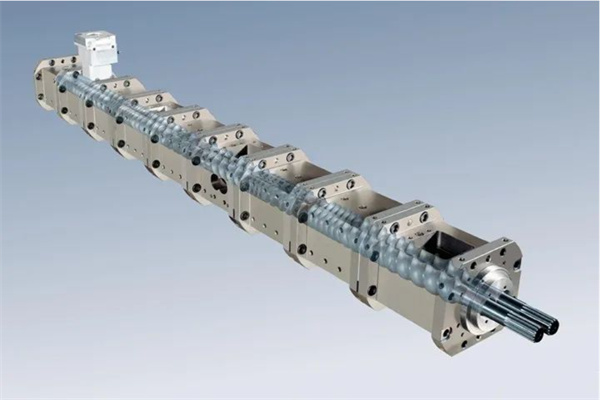

Ịchịkọta gbọmgbọm extruder

Dị ka ọ na-adịkarị, onye na-emepụta ihe ga-agbakọta extruder, na nhazi gbọmgbọm dabara na nhazi usoro achọrọ. N'ọtụtụ usoro ngwakọta, extruder nwere oghere nri na-emeghe na gbọmgbọm nri 1. Mgbe ngalaba nri a gasịrị, e nwere ọtụtụ gbọmgbọm mechiri emechi na-ebufe ihe siri ike, gbazee polymers, na mix polymers gbazee na ihe mgbakwunye ọnụ.

Nchikota cylinder nwere ike dị na cylinder 4 ma ọ bụ 5 ka enye ohere maka nri mpụta nke mgbakwunye, na-esote ọtụtụ cylinders mechiri emechi iji nọgide na-agwakọta. Ọdụ ụgbọ mmiri na-ekpochapụ agụụ ahụ dị nso na njedebe nke onye na-apụ apụ, na-esote gbọmgbọm ikpeazụ mechiri emechi n'ihu isi ọnwụ. Enwere ike ịhụ ihe atụ nke ịgbakọta gbọmgbọm na foto 3.

A na-egosipụtakarị ogologo nke extruder dị ka oke ogologo na dayameta ịghasa (L/D). N'ụzọ dị otú a, mgbasawanye nke ngalaba usoro ahụ ga-adị mfe, dị ka obere extruder na L / D ruru 40: 1 nwere ike gbasaa n'ime extruder na nnukwu dayameta na ogologo L / D nke 40: 1.

Oge nzipu: Eprel-04-2023